SKATEPARKS

Why choose Tiptiptap Skateparks?

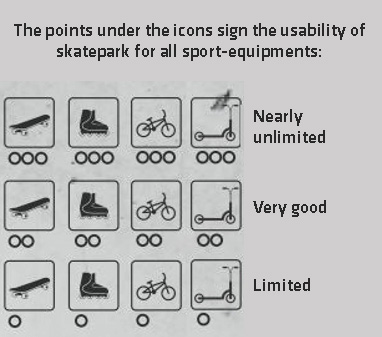

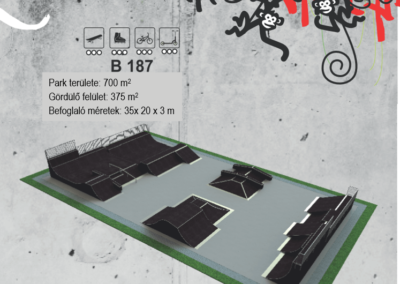

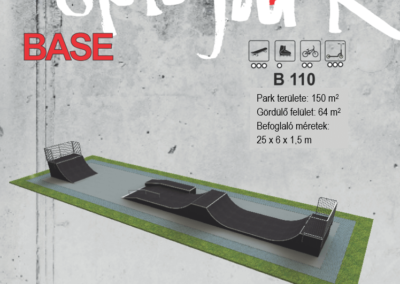

- All skateparks are designed by professional skaters, for skateboarders, roller-skaters, scooters and BMX-riders

- All skatepark equipments are manufactured in accordance with the current safety standard EVS-EN 14974: 2019.

- All elements are manufactured using CNC controlled technology under industrial conditions, which ensures the stability of the support structures, thus ensuring the long life of all products

- We offer a solution for the realisation of custom monolith skateboard ramps.

- The materials used are weather resistant. The rolling surfaces of the products are clad with high quality, high performance, waterproof birch plywood. The rolling surfaces contain an anti-slip phenyl layer.

- Torx screws are used to connect the structural joints.

- As the surface of the equipment is covered with two layers of plywood, only the top layer needs to be replaced when it gets worn over time. This ensures more cost-effective maintenance.

What to consider before ordering a skatepark?

A well functioining skateparks is more than just randomly distributed combinations of elements, therefore we advise to consider the following before purchase.

Location of the planned skatepark:

- In which public space will the skatepark be built?

- What is the available area for the skatepark?

- What is the surrounding area like?

- What is the planned substrate for the skatepark (asphalt, concrete, meadow)?

- What type of buildings are there in the immediate vicinity of the skatepark?

- What is the distance to the nearest road from the skatepark?

- What park architecture elements will be needed adjacent to the skatepark (benches, trash cans, fences, etc.)?

- How will the new skatepark change and affect the current habits and everyday lifestyle of people passing and living nearby?

Skatepark users:

- Who will use the new skatepark?

- What is the intensity of use of the planned park?

- What age and skill level group is the park planned for?

- What will be the main sports equipment used in the new skatepark (BMX, skateboard, scooter or roller skates)?

The needs of users of the planned skatepark:

- Consultation with young people is a great help in the design of the park. The skatepark users really know which elements they would most like to see in the park and which are the most popular. If young users are given the opportunity to participate in the design of the skatepark, they will also take care of the integrity of the park.

Budget for the planned skatepark:

- Consultation with experts: experts (skatepark designer and constructor) should be consulted on the skatepark elements proposed by the future users. The skatepark designer can design and the contractor can place the selected elements in the available area within the budget constraints, and can also ensure that the park is usable and safe.

- Rules for the use of the park: The rules of use of the skatepark should be taken into account at the planning stage. It is recommended that the skatepark is equipped with an informational board with the following information:

- rules for using the ramp

- the name and contact details of the skatepark operator

- contact details for ambulance, police and fire department

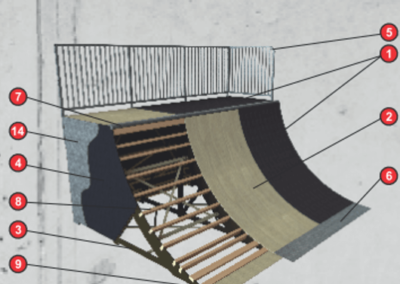

Technical description

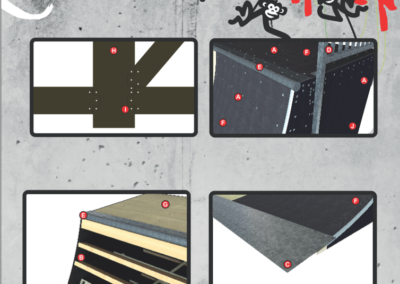

High-quality hardened torx screws of 6×40-90 mm shall be used for all junctions.

- A. The screw heads are countersunk into the surface to ensure safe use.

- The wooden spacers are 45×95 mm cross-section, dried, impregnated and planed. The ends of the planks have a special grip to improve the durability of the wood.

- Galvanised or non-slip coated steel plate (3 mm x 250-500 mm, depending on the type of barrier) is used for the connection to the asphalt.

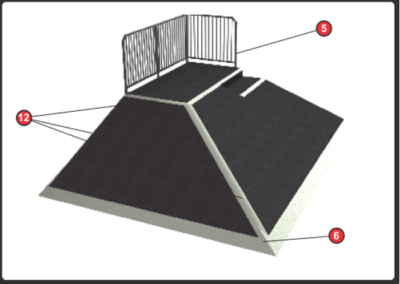

- The parapets are made of galvanised and/or powder coated steel. A wooden guard rail is available for the ECO version.

- The upper edges of the ramps are sealed with a 60×3 mm tubular connecting plate or with 3-5 mm thick hot-dip galvanised or powder-coated angle steel.

- Two layers of plywood are used for the rolling surfaces. The bottom layer fits into special pockets on the edge of the parapet:

- The top layer is 9-15 mm thick waterproof plywood with a 6 mm thick anti-slip rolling surface.

- The structure of the parapet is made of 12-18 mm thick waterproof plywood, but can also be made of HDPE plastic on request. This is equipped on the PRO version.

- The plywood sheets are connected by a puzzle-type joint.

- Basically, the sides of the structure are covered with 9-12 mm thick laminated waterproof plywood, but can be covered with 10 mm thick HDPE plastic on request.

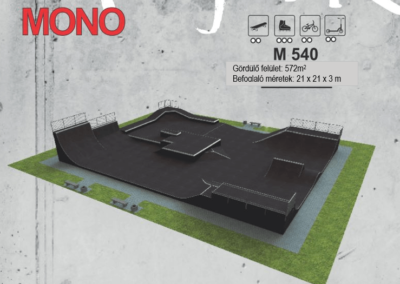

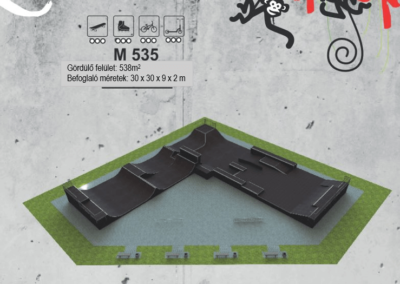

Monolith skateparks

This type of skatepark has a monolithic structure. It can be placed anywhere without an asphalt base. The park is mounted on special concrete poles.

The structure of the parapets is individually designed and patented.

The structure of the equipment is mounted on concrete pillars measuring 300 x 300 x 1500 mm, ensuring the stability and durability.

The entire structure is positioned 100-500 mm above the ground level, which ensures adequate ventilation. This minimises the amount of moisture from the ground to the structure.

Two or three layers of plywood are used for the rolling surfaces. The bottom layer is 9-18 mm thick and the top layer is 9 mm thick waterproof plywood with a non-slip laminate surface.

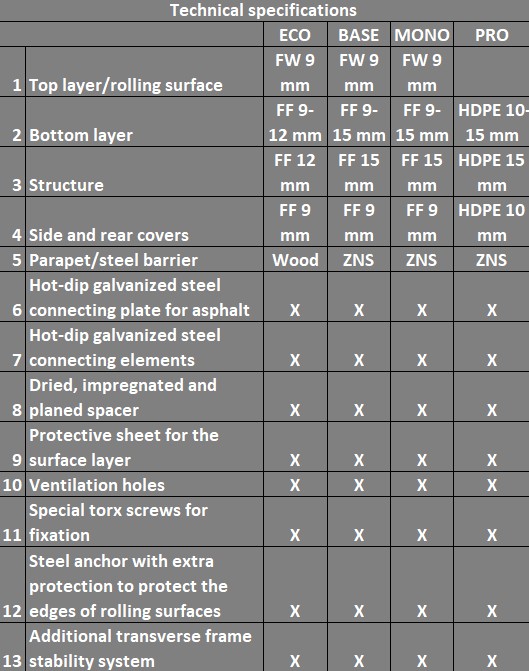

|

FW |

Laminated, waterproof, plywood with non-slip surface |

|

FF |

Waterproof plywood |

|

CC |

Vapour resistant plywood |

|

Rolling surface |

Professional, high durability rolling surface |

|

HDPE |

High density polyethylene plastic |

|

ZNS |

Hot-dip galvanised steel |

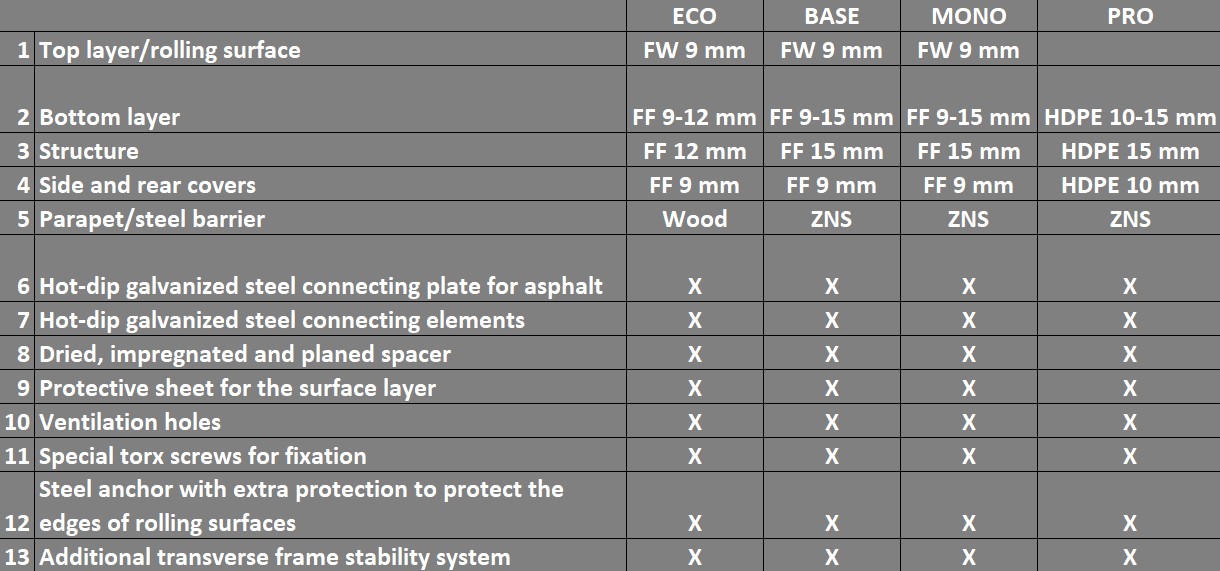

Technical specifications

We undertake the supply of playground, sports and gymnastics equipment and the construction of the project for playground, sports and gymnastics fields for customers, investors and builders, with our own installation and construction teams. Delivery and construction deadlines are agreed in advance.

Have a look at our catalogue and ask for a quote!

ABOUT US

Since 2000, Fadoktor Mérnöki Iroda Kft. and its legal predecessor have been a family business dealing with wood protection, manufacture, distribution and trade of sawmill and further processing industrial products, and especially with the design and construction of playgrounds.

CONTACT

9400 Sopron, New incubator house

Next to the Sopron-Kelet intersection of the M85 expressway. Click here for route planning!

Mo – Fr: 09:00-17:00

Dr. László Németh, CEO

Bence György Katona, Leader of Wood Protection

E-mail: bence.katona@fadoktor-mi.hu

Tel.: +3630/114-8088

Dávid Major, Leader of Planning

E-mail: david.major@fadoktor-mi.hu

Tel.: +3630/114-8099

Orsolya Szemenyeiné Bőr, Assistant

E-mail: fadoktor@fadoktor-mi.hu

Tel.: +3699/386-838

Dániel Márton, Trainee of Timberindustrie

E-mail: daniel.marton@fadoktor-mi.hu

Tel.: +3699/386-838

WHAT WE OFFER

Playgrounds

Wood protection

Outdoor equipment

Dipping tanks

Vacuum-impregnation equipment

Skateparks

© FADOKTOR MÉRNÖKI IRODA KFT. 2023 | Impressum | Privacy Policy | Website: Webpole